A wind turbine is a device that converts kinetic energy from the wind into electrical power. The term appears to have migrated from parallel hydroelectric technology (rotary propeller). The technical description for this type of machine is an aerofoil-powered generator.

The result of over a millennium of windmill development and modern engineering, today's wind turbines are manufactured in a wide range of vertical and horizontal axis types. The smallest turbines are used for applications such as battery charging for auxiliary power for boats or caravans or to power traffic warning signs. Slightly larger turbines can be used for making contributions to a domestic power supply while selling unused power back to the utility supplier via the electrical grid. Arrays of large turbines, known as wind farms, are becoming an increasingly important source of renewable energy and are used by many countries as part of a strategy to reduce their reliance on fossil fuels.

Windmills were used in Persia (present-day Iran) as early as 200 B.C. The windwheel of Hero of Alexandria marks one of the first known instances of wind powering a machine in history.However, the first known practical windmills were built in Sistan, an Eastern province of Iran, from the 7th century. These "Panemone" were vertical axle windmills, which had long vertical drive shafts with rectangular blades. Made of six to twelve sails covered in reed matting or cloth material, these windmills were used to grind grain or draw up water, and were used in the gristmilling and sugarcane industries.

Windmills first appeared in Europe during the Middle Ages. The first historical records of their use in England date to the 11th or 12th centuries and there are reports of German crusaders taking their windmill-making skills to Syria around 1190. By the 14th century, Dutch windmills were in use to drain areas of the Rhine delta. Advanced wind mills were described by Venetian inventor Fausto Veranzio. In his book Machinae Novae (1595) he described vertical axis wind turbines with curved or V-shaped blades.

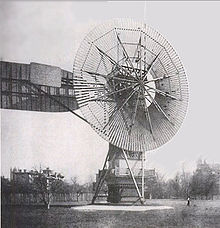

The first electricity-generating wind turbine was a battery charging machine installed in July 1887 by Scottish academic James Blyth to light his holiday home in Marykirk, Scotland. Some months later American inventor Charles F. Brush was able to build the first automatically operated wind turbine after consulting local University professors and colleagues Jacob S. Gibbs and Brinsley Coleberd and successfully getting the blueprints peer-reviewed for electricity production in Cleveland, Ohio. Although Blyth's turbine was considered uneconomical in the United Kingdom electricity generation by wind turbines was more cost effective in countries with widely scattered populations.

In Denmark by 1900, there were about 2500 windmills for mechanical loads such as pumps and mills, producing an estimated combined peak power of about 30 MW. The largest machines were on 24-meter (79 ft) towers with four-bladed 23-meter (75 ft) diameter rotors. By 1908 there were 72 wind-driven electric generators operating in the United States from 5 kW to 25 kW. Around the time of World War I, American windmill makers were producing 100,000 farm windmills each year, mostly for water-pumping.

By the 1930s, wind generators for electricity were common on farms, mostly in the United States where distribution systems had not yet been installed. In this period, high-tensile steel was cheap, and the generators were placed atop prefabricated open steel lattice towers.

A forerunner of modern horizontal-axis wind generators was in service at Yalta, USSR in 1931. This was a 100 kW generator on a 30-meter (98 ft) tower, connected to the local 6.3 kV distribution system. It was reported to have an annual capacity factor of 32 percent, not much different from current wind machines.

In the autumn of 1941, the first megawatt-class wind turbine was synchronized to a utility grid in Vermont. The Smith-Putnam wind turbine only ran for 1,100 hours before suffering a critical failure. The unit was not repaired, because of shortage of materials during the war.

The first utility grid-connected wind turbine to operate in the UK was built by John Brown & Company in 1951 in the Orkney Islands.

Despite these diverse developments, developments in fossil fuel systems almost entirely eliminated any wind turbine systems larger than supermicro size. In the early 1970s, however, anti-nuclear protests in Denmark spurred artisan mechanics to develop microturbines of 22 kW. Organizing owners into associations and co-operatives lead to the lobbying of the government and utilities and provided incentives for larger turbines throughout the 1980s and later. Local activists in Germany, nascent turbine manufacturers in Spain, and large investors in the United States in the early 1990s then lobbied for policies that stimulated the industry in those countries. Later companies formed in India and China. As of 2012, Danish company Vestas is the world's biggest wind-turbine manufacturer.

A quantitative measure of the wind energy available at any location is called the Wind Power Density (WPD). It is a calculation of the mean annual power available per square meter of swept area of a turbine, and is tabulated for different heights above ground. Calculation of wind power density includes the effect of wind velocity and air density. Color-coded maps are prepared for a particular area described, for example, as "Mean Annual Power Density at 50 Metres". In the United States, the results of the above calculation are included in an index developed by the National Renewable Energy Laboratory and referred to as "NREL CLASS". The larger the WPD calculation, the higher it is rated by class. Classes range from Class 1 (200 watts per square meter or less at 50 m altitude) to Class 7 (800 to 2000 watts per square m). Commercial wind farms generally are sited in Class 3 or higher areas, although isolated points in an otherwise Class 1 area may be practical to exploit.

Wind turbines are classified by the wind speed they are designed for, from class I to class IV, with A or B referring to the turbulence'

Not all the energy of blowing wind can be used, but some small wind turbines are designed to work at low wind speeds.

Conservation of mass requires that the amount of air entering and exiting a turbine must be equal. Accordingly, Betz's law gives the maximal achievable extraction of wind power by a wind turbine as 59% of the total kinetic energy of the air flowing through the turbine.

Further inefficiencies, such as rotor blade friction and drag, gearbox losses, generator and converter losses, reduce the power delivered by a wind turbine. Commercial utility-connected turbines deliver 75% to 80% of the Betz limit of power extractable from the wind, at rated operating speed.

Efficiency can decrease slightly over time due to wear. Analysis of 3128 wind turbines older than 10 years in Denmark showed that half of the turbines had no decrease, while the other half saw a production decrease of 1.2% per year

No comments:

Post a Comment